Part Sorting

Part sorting is an important method for manufacturing enterprises to improve the reuse rate of parts and reduce the number of parts. It is also a difficult problem for many manufacturing enterprises. So many parts will inevitably bring management pressure to enterprises; At the same time, it must be time-consuming and labor-consuming for engineers to select suitable parts from so many parts

Why Do You Want The Part Sorting

The direct goal of automatic parts sorting management is to facilitate user retrieval, improve the reuse rate of parts, reduce the number of parts, improve efficiency, and reduce the increased cost and time cost due to the development of new parts. The classified management of parts and components can at least bring benefits in the links of design, process, procurement, and manufacturing. From the aspect of design, the effective part sorting machine can help engineers quickly retrieve suitable or similar parts for direct reuse, or improve the design based on similar parts to improve the design efficiency.

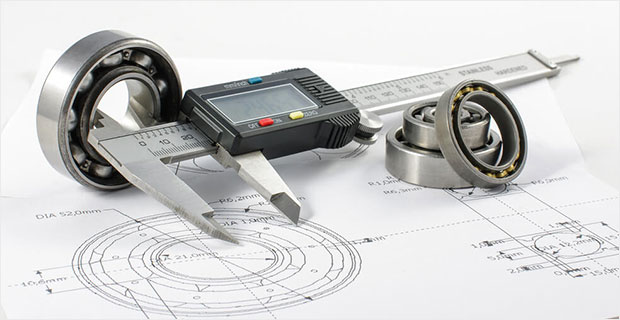

Part Sorting & Inspection Services

Part sorting is only the phased goal of the system. The highest goal of the system is to directly apply the data and files searched by the sorting method to all stages of product development through the method of small part sorting machine, so as to finally support CAD, NC programming, and process flow planning, and significantly accelerate the production speed of products. Information sorting can help customers search standard parts more quickly and conveniently, which is much better than manual search. Experience shows that the more easily a design engineer can find similar or homologous parts, the more likely he is to use the past design again and make design changes based on it, which can greatly accelerate the speed and efficiency of product research and development.

Custom-Made To Order Service For Sorting And Inspection

- In-depth examination of the project: Issues and requirements to ensure that budget and timeline constraints are satisfied.

- Process Development: Created specifically for your project, taking into consideration all of its specific requirements.

- Inspection: Parts are inspected and evaluated by certified metrologists.

- Part sorting conveyor is the categorization and separation of objects under professional supervision.

- Putting Labels on Things: Parts that are designated with basic to in-depth information

- Reporting: Insightful reports that are customized to your requirements

- Rework: When necessary, products are repaired and packed.